Live Machine Demos Available!

Contact Us

#1 UV Coating Machine Manufacturer

Go Shop

Are you looking to make the most of your workspace without having to sacrifice performance of a professional UV coater? We have your solution! The TruCoat MINI is designed with the short run printer in mind. It offers a fantastic finish all while being the smallest footprint production UV coater available on the market.

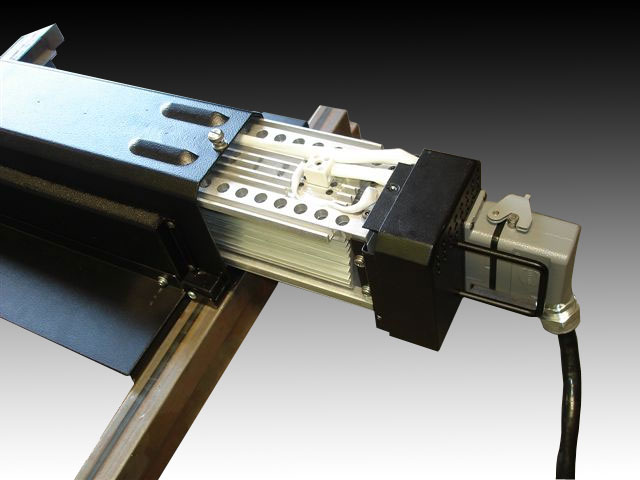

The TruCoat MINI is small but incorporates all the features of larger units including a peristaltic fluid pump, IR Lamps for flow-out and adhesion and a stainless steel doctor blade to ensure the ability to run double-sided work. In three short minutes you can set-up the unit and begin producing stunning UV coating. The TruCoat MINI is the answer for today’s short run printer.

Read more

- Small footprint (Under 10 sq. ft.)

- 3-minute set-up and cleanup

- Adjustable intensity IR for flow-out and adhesion

- 3 roll applicator system with doctor blade

- Easy to adjust roller gaps

- HD duty casters for mobility

- Enclosed design for noise reduction in office environments

- Offset and digital

- Xerox

- Ricoh

- Konica Minolta

- Canon

- HP

- OCE

- Screen digital

- Xante

- Power: 208-220 1ph 60hz 25amps

- Format: 14” x any length

- Paper Weight: 100lb text to 30 point

- Dimensions of Unit: 40”x 32”

The TruCoat (Hand Fed) UV Coater is truly a unique coating technology. Its sophisticated design can increase your profit margin by enhancing the aesthetic quality of your products and diversify product offerings.It was designed from the ground up to offer the very best in performance and simplicity. TruCoat technology can provide your business the highest possible UV coating available, and is simple enough for anyone to operate.

Some features include an “Easy to Use” touch screen, variable intensity IR lamps and quick-change rollers that take only 5 minutes to replace. The TruCoat system is the ultimate coating solution to help you become a threat in your business.

Read more

- Modular design for future upgrades to automated feeders and stackers

- Apply gloss-satin and matte coatings

- Coat toner based, offset or inkjet with ease

- Quick change textured rollers for an array of finishes

- Speeds of up o 4,000SPH

- High production auto-feeders and stackers available

- From start to coating in less than 5 Minutes

- Less than 10 minutes to switch between different coatings

- 0 VOC UV coating and wash-up fluid

- UV coated documents are 100% recyclable

- LESS THAN ½ PENNY PER SQFT

- Modern/compact design

- All steel construction

- 3 roll application system with quick-change roller design

- Stainless steel doctor blade

Want the best of both worlds? The Inline UV Coater offers all of the same features of the sophisticated TruCoat UV Coater, with added capabilities. This innovative design was created to accommodate and adapt to your existing printing equipment flawlessly. With its easy transfer inline conveyor table, professional UV coating becomes an accessible reality for your finishing needs. This technology offers high performance coating, and a quick and easy transport system to keep up with your fast-pace business.

Read more

- Works with all DIGITAL outputs

- Easy inline integration with most digital presses

- Graded transport conveyor for seamless transfer

- Adjustable height transfer table

- Modular design for easy mobility

- IR/UV combo to assist in flow-out and coating adhesion

- 5 minute start up and clean up

- Dual fluid lines for easy coating changeover

- Offset and digital

- Xerox

- Ricoh

- Konica Minolta

- Canon

- HP

- OCE

- Screen digital

- Xante

- Power: 208-220V/60Hz/ 30 Amps+

- Up to 3,600 SPH

- Min 100lb Text

- 120 FPM

- XCI-18

- TRUV-16IL

In addition to our full line of UV coaters, TEC Lighting also offers an impressive and proven variety of UV coating to compliment both TEC and other UV coaters. With the TEC Coat line of UV coating, you can be rest assured that you will experience consistent finishes from the beginning to the end of a production run. TEC Lighting has formulated proven ultraviolet, cured coatings in a variety of gloss ranges including gloss, satin and matte.

TEC Coat UV Coating is applied by flooding a sheet of paper with a specialized UV solution, and then transferred under resilient UV lighting. The UV coating dries instantaneously, revealing a reflective and vibrant finish, without the sticky effects of conventional UV coatings. In addition to professional aesthetic quality, TEC Coat UV Coatings act as a barrier for printed materials, preventing scuffs and scratches.

Whether you’re looking for a finish that is dry-erase, glue-able, write-able, or for offset and digital presses, the TEC Coat offers an array of applications that can fulfill your custom curing needs. TEC Coat UV Coating is always 100% VOC free and contains no harmful irritants.

Read more

The MegaCoat UV Coater is a high production UV coater designed for the most demanding workload of mid/large offset printers looking to add flood UV coating offline. This machine is a cost effective alternative to the high cost of adding a UV coating station on press.

It is offered in both 32” and 45” configurations to satisfy your accommodations. This versatile appliance is comprised of a high-capacity pallet load rear pickup steam feeder, heavy duty coating station with 7” diameter rollers, conveyor system with 4 IR lamps and 2 UV lamps and a pallet unload receding stacker. It is rated at 7,500 SPH at 20”x 28” and 5,500 SPH at 28”x 40”.

Read more

- All steel construction

- Pallet load stream feeder with Becker Air Pump

- 3 roll applicator with 7” diameter rollers

- Stainless steel doctor blade to ensure proper cleaning of the impression roller

- Variable speed metering roller to control the amount of coating applied to the sheet

- Vacuum hold-down conveyor with dual UV lamps

- PLC touch screen controlled with sheet counter

- Self-tracking conveyor belt

- Adjustable IR lamps for coating flow out

- Offset and digital

- Xerox

- Ricoh

- Konica Minolta

- Canon

- HP

- OCE

- Screen digital

- Xante

- Power: 208-220V 60hz 3ph 120amps

- Format: 42”x 32”

- Speed: up to 7,000 SPH

- Stock Thickness: 70lb cover to 40-point cover

Do you have exceptionally large printing materials that need a “finishing touch”? Look no further than the MegaCoatXL. Just like its name, the MegaCoatXL accommodates to your sizable product needs. This UV coater is the perfect solution for wide formatcoating demands. From posters to custom graphic displays, TEC Lighting’s MegaCoatXL offers professional UV solution that certifies precise coating up to 63 inches.

This high-speed piece of equipment ensures affordability without sacrificing quality. TEC Lighting Technology guarantees systemic accuracy that provides only the best in aesthetic perfection.

Read more

- Available in 63-inches

- Process speed to 70 fpm

- UV process ready indicator

- Digital speed controls ensure repeatable performance

- Advanced curing unit design features parabolic reflector and short run out engineering

- Scraper blade system prevents coating transfer to bottom of prints

- Nip adjusts up to 1.5 inches, can coat substrates up to 1.25 inches thick

- UV light shield

- 1 year warranty parts/6 month warranty labor

- Peristaltic pump

- Custom feeders and receiving tables available

- Modular roll-to-roll designed stations

- Offset

- Gerber

- Mimaki

- OCE

- HP Syntex

- Epson

- Gandi Design

- Canon

- Any ink jet technology

- UV-curable roll-fed and flatbed printers

- Solvent roll-fed models

- Eco-solvent roll-fed models

- Latex printers

CF745

TEC Lighting UV Coaters are designed to be vented outside the facility to prevent ozone and slight odor. If you are unable to vent the UV coater as recommended, you can rely on the PURE Air,Activated Carbon System to get the job done. The PURE Air carbon filter will help eliminate the ozone and odor produced by certain coating materials. This device can either be mounted directly to the UV coater or placed in the room to scrub the entire air content of that room.

Although TEC UV coating is 100% VOC free, there is a slight discharge of odor during the coating process that the PURE Air can help eliminate. In addition, the PURE Air can also be used in conjunction with wide format printers and other environments where VOC’s and particles need to be removed from the air.

With a small and modular design, the PURE Air filters are ideal for enclosed rooms without adequate ventilation. PURE Air filters can easily be installed onto any 3”,4” or 6” exhaust ports, with CFM rating from 100- 1000. Just another step into the Eco-friendly Green Zone.

Read more

TEC Lighting’s Supreme Series conveyor systems are manufactured to provide superior performance of UV curable finishes. We design each system around the customer’s specific requirements. These systems are equipped with a closed loop cooling system with both vertical and horizontal ambient airflow. The vertical airflow also acts as vacuum hold-down for lighter weight substrates and excess fume exhaust. Our rugged conveyor top is lined with a Teflon-coated fiberglass mesh belt to transfer many different types of substrates at variable speeds up to 300 feet per minute (8000 sheets per hour).

The adjustable lamps can be focused to improve both temperature and UV spectral output. The Supreme Series power supply is located directly below the conveyor and lamp housing and acts as the base for the entire system. The system comes standard with a 400wpi mercury vapor lamp. These conveyor systems are mobile. Their heavy-duty metal casters allow the system to be reconfigured and to move from press to press with great flexibility.

Read more

TEC Lighting’s WebCure lamp heads feature state-of-the-art technology and design. These advanced features, coupled with the flexibility of fitting almost any press type, have made TEC Lighting an industry leader in UV curing technologies. The WebCure UV curing system provides outstanding performance and reliability with current applications in the printing, packaging, plastics, wood, and electronics industries. TEC Lighting is known as “The first name in UV curing solutions.”

Our customized “Cool Option” consists of an optically balanced package, which provides the ability to run high-heat sensitive substrates. Our special combination of dichroic filters, hot-mirrored quartz barrier glass, and our closed-loop auto damper heat management package enables our system to cure at both low and high print speeds without the use of chill rolls.

The heat management cooling system is linked through a dedicated blower, which is driven through the power supply. The system uses RTD sensors, thermocouples and an auto damper all looped through a digital thermostat for optimum heat management.

The TEC Lighting lamp cassettes come standard with mercury vapor lamps. Cassettes are easily removable for serviceability and for mobility from station to station. Our multi-focal point, highly polished elliptical reflectors enable maximum UV spectral output while also acting as a clam-shell shutter mechanism, providing web protection in press idle mode. Our single Uni-Cable design provides lamp power, pneumatics and lamp controls along with the utility of quick disconnects.

The state-of-the-art in power supplies and operation controls

TEC Lighting offers a comprehensive selection of power supplies and operator control panels to meet a variety of commercial needs. Our state-of-the-art ballast control feature maintains consistent power levels regardless of minor voltage irregularities or ambient temperature fluctuations. Available in both 50 and 60 hertz models and various voltages, all components are UL, CSA, and CE approved for the highest in quality and design.

The WebCure Series 3000 command center is a logic-based relay system with (3) three manual power settings and a remote operator control panel. It is equipped with a two-position damper linked with an RTD sensor to an analog exhaust temperature controller. These interlinked components maintain constant and accurate lamp temperatures. The system is built performance tough and is very cost efficient. The 3000 series comes in single and double lamp configurations.

The WebCure Series 4000 command center was designed especially for the Narrow Web-flexo market, where presses are equipped with UV interface options. These presses already have connections available, to which we can interface with features such as a shutter operation signal with real press speed and auto power-ramping. The logic-based relay system has the three power settings and remote control found on the 3000 series as well as a manual cool down mode and an emergency stop. The 4000 Series has the cooling capabilities of the 5000 Series with a digital thermostat and an auto-damper temperature feedback cooling system. The 4000 Series also comes in single and double lamp configurations.

The WebCure Series 5000 command center is the thoroughbred of our systems. The 5000 Series standard PLC controls provide for easy changes to the lamp operating system. Program set-up parameters facilitate the operator/equipment interface, and a remote touch-screen interface is standard on multi-lamp systems. The 5000 Series comes equipped with the digital thermostat and auto damper temperature feedback cooling system to preserve optimal substrate temperatures.

Standard PLC Operating Options Include:

Read more

- Individually programmable lamp shutter timing.

- Individually programmable power ramping.

- The “Systems Interface” provides interactivity between our PLC and competitors’ Legacy

Categories

© Copyright 2021 | Tec Lighting - All Rights Reserved | Created by Prince O.