Live Machine Demos Available!

Contact Us

#1 UV Coating Machine Manufacturer

Go Shop

High speed web UV and AQ at speeds of up to 125 m/min

Chamber anilox coating system for uniform controlled coating application

Double UV lamp system for perfect UV curing

Seamless connection to your existing printing line or can be used offline with any unwind and rewind.

Attractive price point that maximizes profit from day 1

Read more

TRUCOAT Stand alone automatic receding stacker, Width: 16" 21" and 30" Length: 26", Min/Max paper weights: 150gsm – 600gsm, up to 3,500 sheets/hour

Read more

- 22" deep pile receding stacker

- HD double chain lift

- Speeds to match all TRUCOAT UV Coaters

- Easy unload w/ wheeled tray

- pneumatic controlled jogger plate

The TruCoat (Auto Fed) UV Coater is truly a unique coating technology. Its sophisticated design can increase your profit margin by enhancing the aesthetic quality of your products and diversify product offerings.It was designed from the ground up to offer the very best in performance and simplicity. TruCoat technology can provide your business the highest possible UV coating available, and is simple enough for anyone to operate.

Some features include an “Easy to Use” touch screen, variable intensity IR lamps and quick-change rollers that take only 5 minutes to replace. The TruCoat system is the ultimate coating solution to help you become a threat in your business.

Read more

- Modular design for future upgrades to automated feeders and stackers

- Apply gloss-satin and matte coatings

- Coat toner based, offset or inkjet with ease

- Quick change textured rollers for an array of finishes

- Speeds of up o 4,000SPH

- High production auto-feeders and stackers available

- From start to coating in less than 5 Minutes

- Less than 10 minutes to switch between different coatings

- 0 VOC UV coating and wash-up fluid

- UV coated documents are 100% recyclable

- LESS THAN ½ PENNY PER SQFT

- Modern/compact design

- All steel construction

- 3 roll application system with quick-change roller design

- Stainless steel doctor blade

Do you have exceptionally large printing materials that need a “finishing touch”? Look no further than the MegaCoatXL. Just like its name, the MegaCoatXL accommodates to your sizable product needs. This UV coater is the perfect solution for wide formatcoating demands. From posters to custom graphic displays, TEC Lighting’s MegaCoatXL offers professional UV solution that certifies precise coating up to 50 inches.

This high-speed piece of equipment ensures affordability without sacrificing quality. TEC Lighting Technology guarantees systemic accuracy that provides only the best in aesthetic perfection.

Read more

- Available in 50-inches

- Process speed to 70 fpm

- UV process ready indicator

- Digital speed controls ensure repeatable performance

- Advanced curing unit design features parabolic reflector and short run out engineering

- Scraper blade system prevents coating transfer to bottom of prints

- Nip adjusts up to 1.5 inches, can coat substrates up to 1.25 inches thick

- UV light shield

- 1 year warranty parts/6 month warranty labor

- Peristaltic pump

- Custom feeders and receiving tables available

- Modular roll-to-roll designed stations

- Offset

- Gerber

- Mimaki

- OCE

- HP Syntex

- Epson

- Gandi Design

- Canon

- Any ink jet technology

- UV-curable roll-fed and flatbed printers

- Solvent roll-fed models

- Eco-solvent roll-fed models

- Latex printers

THIS ITEM IS NO LONGER IN PRODUCTION. PARTS AND SERVICE AVAILABLE ONLY.

The Tec Lighting XtraCoat Offline UV Coating system offers the ideal combination of performance and affordability. The XtraCoat lineup was designed with your needs and desires as a main priority. The XtraCoat Offline UV Coater will give you the ability to Gloss and Satin coat almost any printed sheet with ease. The system is offered in many configurations to fit your requirements, sizes range from 18” to 30” with a modular design to allow for added components such as an automatic feeder for increased production in the future. Let us show you the increase in capabilities and profit that you can achieve with the addition of the Tec Lighting XtraCoat Offline UV Coating system.

Read more

With TEC Lighting you can expect high-quality standards for “Portable Searchlights”. The TECSAR Light offers incredible levels of blinding white light, averaging 4,000 luminous flux....

Read more

The Supreme Lighting source for today’s industry.

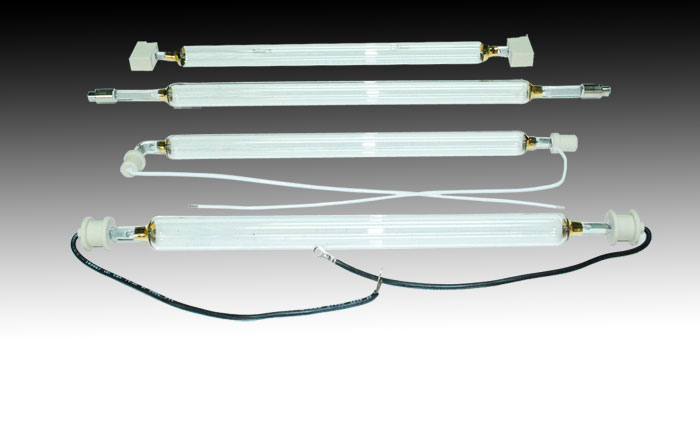

TEC Lighting provides standard and specialty application lighting products for industries involved in printed circuit board fabrication, medical & scientific instrumentation, machine vision, CD manufacturing, water purification, cinema projection, video projection, live-stage entertainment, theme park attractions, plate-making, solar simulation, pharmaceutical testing, plastics, wood coating, and printing. TEC Lighting is an industry leader in the manufacturing and distribution of the following product lines:

Read more

- UV Curing Lamps

- Short-Arc Xenon Lamps

- Mercury Capillary Lamps

- Metal Halide Exposure Lamps

- Stage & Studio / HMI Lamps

- Flash-Pulse Xenon Lamps

- Low-Pressure UV Germicidal Lamps

- Black Light / Black Light Blue Lamps

- Fiber Optic Light Source Lamps

- Short-Arc Mercury Xenon Lamps

- Additive Lamps

- Graphic Arts Lamps

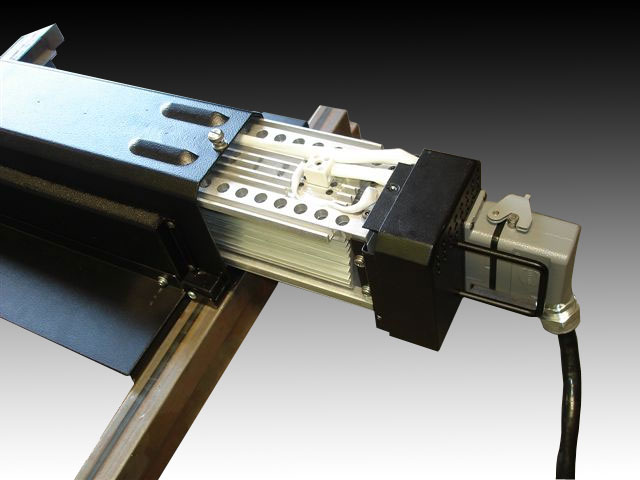

TEC Lighting’s WebCure lamp heads feature state-of-the-art technology and design. These advanced features, coupled with the flexibility of fitting almost any press type, have made TEC Lighting an industry leader in UV curing technologies. The WebCure UV curing system provides outstanding performance and reliability with current applications in the printing, packaging, plastics, wood, and electronics industries. TEC Lighting is known as “The first name in UV curing solutions.”

Our customized “Cool Option” consists of an optically balanced package, which provides the ability to run high-heat sensitive substrates. Our special combination of dichroic filters, hot-mirrored quartz barrier glass, and our closed-loop auto damper heat management package enables our system to cure at both low and high print speeds without the use of chill rolls.

The heat management cooling system is linked through a dedicated blower, which is driven through the power supply. The system uses RTD sensors, thermocouples and an auto damper all looped through a digital thermostat for optimum heat management.

The TEC Lighting lamp cassettes come standard with mercury vapor lamps. Cassettes are easily removable for serviceability and for mobility from station to station. Our multi-focal point, highly polished elliptical reflectors enable maximum UV spectral output while also acting as a clam-shell shutter mechanism, providing web protection in press idle mode. Our single Uni-Cable design provides lamp power, pneumatics and lamp controls along with the utility of quick disconnects.

The state-of-the-art in power supplies and operation controls

TEC Lighting offers a comprehensive selection of power supplies and operator control panels to meet a variety of commercial needs. Our state-of-the-art ballast control feature maintains consistent power levels regardless of minor voltage irregularities or ambient temperature fluctuations. Available in both 50 and 60 hertz models and various voltages, all components are UL, CSA, and CE approved for the highest in quality and design.

The WebCure Series 3000 command center is a logic-based relay system with (3) three manual power settings and a remote operator control panel. It is equipped with a two-position damper linked with an RTD sensor to an analog exhaust temperature controller. These interlinked components maintain constant and accurate lamp temperatures. The system is built performance tough and is very cost efficient. The 3000 series comes in single and double lamp configurations.

The WebCure Series 4000 command center was designed especially for the Narrow Web-flexo market, where presses are equipped with UV interface options. These presses already have connections available, to which we can interface with features such as a shutter operation signal with real press speed and auto power-ramping. The logic-based relay system has the three power settings and remote control found on the 3000 series as well as a manual cool down mode and an emergency stop. The 4000 Series has the cooling capabilities of the 5000 Series with a digital thermostat and an auto-damper temperature feedback cooling system. The 4000 Series also comes in single and double lamp configurations.

The WebCure Series 5000 command center is the thoroughbred of our systems. The 5000 Series standard PLC controls provide for easy changes to the lamp operating system. Program set-up parameters facilitate the operator/equipment interface, and a remote touch-screen interface is standard on multi-lamp systems. The 5000 Series comes equipped with the digital thermostat and auto damper temperature feedback cooling system to preserve optimal substrate temperatures.

Standard PLC Operating Options Include:

Read more

- Individually programmable lamp shutter timing.

- Individually programmable power ramping.

- The “Systems Interface” provides interactivity between our PLC and competitors’ Legacy

Categories

© Copyright 2021 | Tec Lighting - All Rights Reserved | Created by Prince O.